Pursuit of the manufacturing that produces only a good part from the first

METALART is pursuting “the manufacturing that produces only a good part from the first”, which is difficult to achive in hot forging. In the past, we inspected the manufactured products and then guaranteed the quality. However, in future we aim to find manufacturing conditions where nothing but accurate products are produced, so that we can give 100% quality assurance for the parts. Once we find such an environment, we will manufacture our products under these conditions and give a complete guarantee of product quality.

Digitizing particular feel and know-how of craftsmen for their work

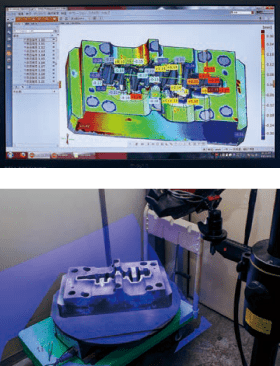

Our company is implementing reforms which enable young employees with little experience to produce high-quality products equivalent to those produced by craftsmen. For that purpose, we digitize conventional work with the particular feel and know-how of the craftsmen, using a high-precision 3D scanner, thermography, and other processes, and feed back the data on drawings and standards. Dies become worn after they are used several times, and are discarded. Conventionally, we rely on the particular feel and know-how of the craftsmen to judge whether the dies shoud be discarded or not. Our company is working on digitizing the criteria for the craftsmen’s particular feel and know-how, and using the dies until they reach the technical limit. Applying this method extends the life of dies for crankshafts by approximately 50%, resulting in significant cost reduction.