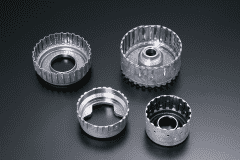

Precision forged auto parts, construction machinery parts, industrial machinery parts, and ship parts.

METALART manufactures products for various sectors. Since METALART has thorough knowledge of the characteristics of steel as forging material, METALART can decide on the processes that provide maximum benefits. Thus we offer products which meet customers' varied requirements.

What is Forging?

“Forging” is a process in which metal materials are pressed or hammered into required shapes.

This forming process permits the manufacture of products where the grain flow follows the contour of the products, due to grain refining. Complicated products with greater toughness can be manufactured. In addition, machining allowance in the post-process of machining is small. Forged products have higher strength compared with castings or products machined from bar stock, so these products are used as critical parts when safety is vital.

The following are the forging processes where the technology of METALART stands out.

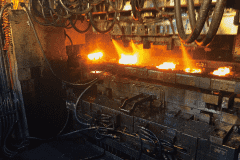

Hot Forging

■ Production of parts having complex shapes and high accuracy at extra-low cost

Hot forging that can manufacture parts with complex shapes at low cost. In order to attain higher product accuracy in hot forging, we at METALART have repeatedly verified our forging technologies from material sizing to forging temperature control and die making, and developed and introduced new technologies. The higher accuracy thus attained has provided reductions in machining, an extra-low forging cost, and shorter delivery times. We can also give individual responses, such as meeting detailed requirements for a variety of forgings in small lots.

Cold Forging

■ Net-shape forging that greatly reduces subsequent processes

Cold forging is a highly-productive forging process that provides lots of benefits. Hot forged surfaces form oxide layers, but the surfaces of cold forged products do not. They are also higher in dimensional and shape accuracy, which enables drastic reductions in machining as a post-forging process. We make positively enhancements to this department by adding a variety of equipment.

Precision Duplex Forging

■ We are ahead of other forgers in the development of duplex forging to manufacture forgings which are near-finished products

We led the world in developing duplex forging, which is a combination of the hot forging and cold forging processes to manufacture forgings with shapes unachievable through machining alone. Since then, we have pioneered mass production of precision forgings with complex shapes and combined high accuracy and strength, such as an involute spline with back-tapered gears, to meet the diverse needs of our customers.

Flow Forming

■ Roll forming to manufacture thin-walled parts with tooth profiles where weight saving and complex forming is required

It is flow forming which has made it possible to form these thin-walled parts, which had not been possible to form with conventional forging technology. We introduced a flow forming machine from Germany, where the machine was developed, to manufacture light-weight finished parts with complex shapes that have achieved a high reputation with our customers.

Machining

■ Aqcuisition of machining technology up to the finished product

In the machining field, METALART in addition to the conventional blank machining, have aquired the technology from the heat treatment (carburization) to the grinding. Thus we conduct process design, development, and production preparation from the beginning to the end of a process. This always enables us to offer most suitable shapes and machining methods with the viewpoint of finished products. In addition, we have achieved reduction in production lead time and downsized production system by integration of quality and production control. With these, we develop highly competitive functional parts and provide them with the customers.